Understanding your tractor's hydraulic system is crucial for efficiency and longevity. A hydraulic flow meter provides invaluable insights into fluid usage, helping identify potential problems before they escalate into costly repairs. For more in-depth troubleshooting, see our guide on tractor hydraulics. This guide simplifies the process of selecting and using the right flow meter for your tractor.

Figuring Out Your Flow Meter Needs

Before purchasing, assess your tractor's hydraulic system. What's the typical flow rate (liters/minute or gallons/minute)? This determines the required meter range. What's the maximum system pressure (PSI or bar)? Safety is paramount; select a meter exceeding this pressure rating. Do you need unidirectional (one-way) or bidirectional (two-way) measurement? Double-acting cylinders require bidirectional meters. Simpler systems might only need unidirectional.

Types of Hydraulic Flow Meters

Several types of flow meters cater to various needs.

Inline Flow Meters: These permanently installed meters provide continuous monitoring. They are generally cost-effective for routine checks. Think of them as a simple, always-on gauge for your hydraulic system's health.

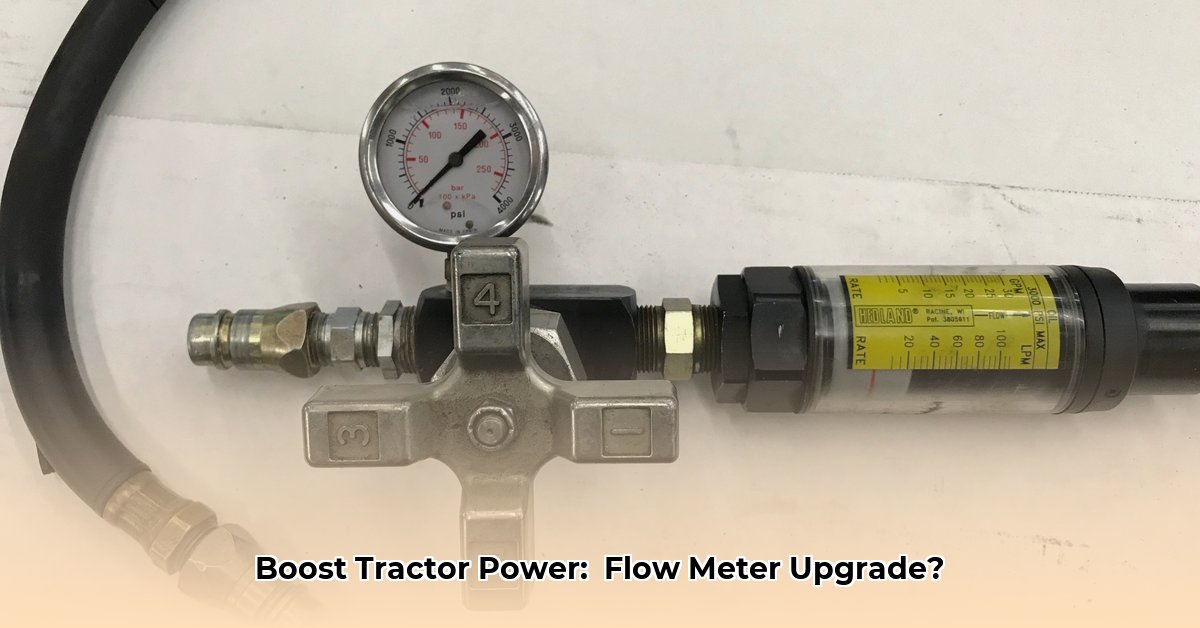

Flow Meter Test Kits: These portable kits are ideal for troubleshooting. They offer adaptability and require no permanent installation. They often include multiple adapters for compatibility with various hydraulic fittings.

Meters with Integrated Load Cells: These advanced meters combine flow and pressure measurement, offering comprehensive hydraulic performance data. They are excellent for in-depth diagnostics and pump testing. A pressure relief valve is a critical safety feature in these meters.

Bidirectional Meters: These measure flow in both directions, essential for systems using double-acting cylinders where fluid flows back and forth. They provide a complete flow picture and are critical for precise diagnostics.

Choosing Your Flow Meter: A Simple Guide

The optimal choice depends on several factors. This table summarizes key considerations:

| Feature | System Needs | Meter Recommendation |

|---|---|---|

| Flow Rate | Low, Medium, High | Match your system's flow rate. |

| Pressure Rating | Low, Medium, High | Exceed your system's maximum pressure. |

| Flow Direction | Unidirectional or Bidirectional | Bidirectional for double-acting cylinders; otherwise, unidirectional might suffice |

| Application | Continuous monitoring or occasional checks | Inline for continuous; Test Kit for occasional. |

| Budget | Tight or Generous | Balance features and price. |

Installation and Upkeep

Installation is usually straightforward, following the manufacturer's instructions. However, for high-pressure systems, a qualified mechanic is strongly recommended to ensure correct installation and compatibility. Regular calibration maintains accuracy.

Safety First

High-pressure hydraulic systems demand caution. Always:

- Use pressure relief valves to prevent dangerous pressure buildup.

- Wear appropriate safety glasses and gloves.

- Seek professional training if inexperienced with hydraulic systems.

- Consult a hydraulics professional when uncertain about any aspect of the process.

How to Choose the Best Bidirectional Hydraulic Flow Meter for High-Pressure Applications

Optimizing your tractor's high-pressure hydraulic system requires a precise bidirectional flow meter. Accuracy, pressure tolerance, fluid compatibility, ease of installation, durability, and long-term cost are all key considerations.

Key Considerations:

- Accuracy: Precise measurement is critical to avoid inefficiencies and potential damage.

- Pressure Tolerance: The meter must comfortably handle the system's pressure.

- Fluid Compatibility: Ensure compatibility with the hydraulic fluid used.

- Installation: The meter should fit easily within the existing layout and be accessible for maintenance.

- Reliability and Durability: A robust meter is essential to minimize downtime.

- Long-Term Cost: Factor in ongoing maintenance and potential replacement costs.

Meter Types: A Comparison

Several meter types suit high-pressure applications, each with advantages and disadvantages:

| Meter Type | Pros | Cons | Suitability for High-Pressure Applications |

|---|---|---|---|

| Turbine | High accuracy, wide flow range, relatively low cost | Vulnerable to wear, limited pressure range in some models | Good (with pressure-rated models) |

| Electromagnetic | No moving parts, wear-resistant, suitable for conductive fluids | Less accurate at low flow rates, fluid conductivity sensitivity | Good (with proper selection and calibration) |

| Differential Pressure | Simple design, relatively inexpensive | Accuracy affected by pressure changes, requires straight pipe runs | Limited, requires careful consideration |

| Coriolis | High accuracy, direct mass flow measurement, independent of fluid properties | Expensive, complex design, may require specialized installation | Excellent (for demanding applications) |

Choosing a Bidirectional Meter

For bidirectional measurement, ensure the selected meter accurately measures flow in both directions. Some meters are inherently unidirectional; others offer bidirectional capability through specialized sensors or algorithms.

Installation and Maintenance

Correct installation is crucial. Follow the manufacturer's instructions meticulously. Regular calibration and maintenance ensure long-term accuracy and reliability. Preventing small problems avoids larger, more costly ones in the future.